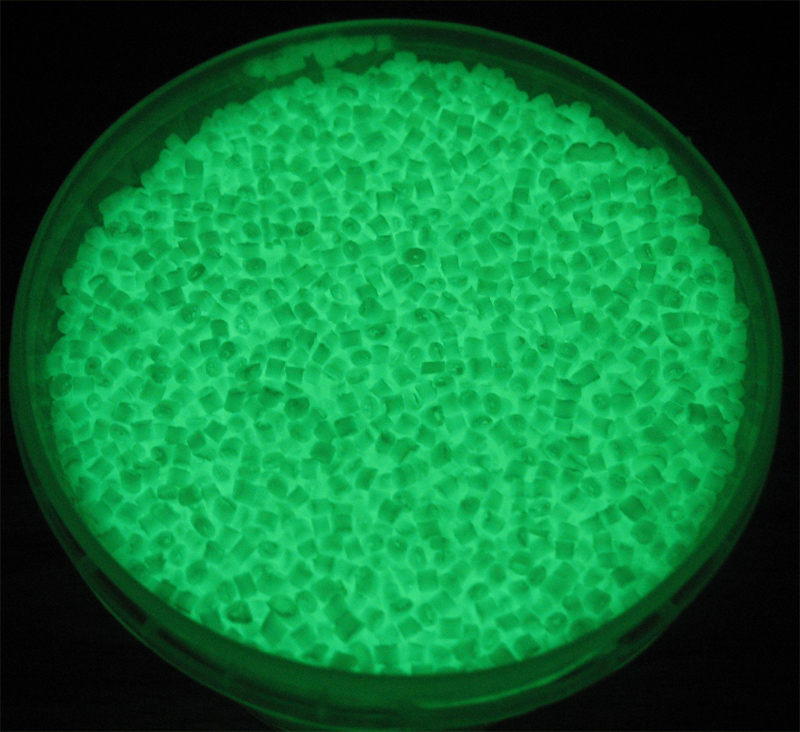

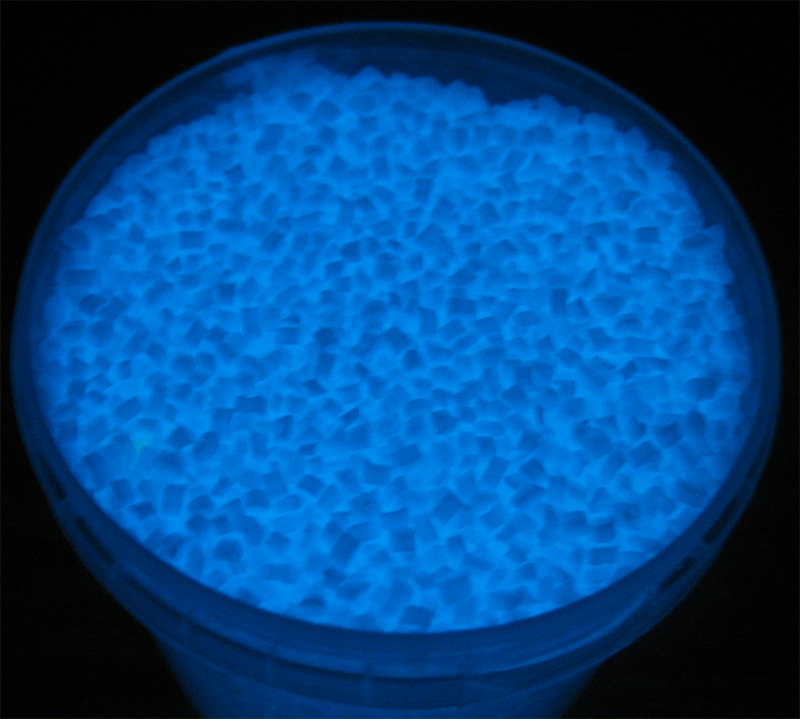

Photoluminescent masterbatch

Glow in the dark masterbatch / Plastic raw material auxiliary masterbatch

Stronger long after-glow photoluminescent performance

Perfect compatibility, easy to operate

Suitable for various manufacturing processes: injection molding, co-extrusion, film blowing, wire drawing

Short Storing-light time:10-20 min;

Long afterglow time: 8~12 hours;

High luminance

Wide excitation wavelength:200-450nm,e.g. visible light, Lamp light,UV light;

Photoluminescent Pigment Recycle time:More than 10 years;

Safty:non-toxic/non-radioactive/nonexplosive/incombustibly/pro-environment

Function of glow in the dark masterbatch

1.Excellent dispersing and heat resistant performance.

2.High quality color masterbatch can ensure the stability of color, consistency of product .

3. High tinting strength, Excellent compatibility with the raw material.

4, Material type: ABS, PP,PE,PVC, PS, PC, AS,PET, Acrylics etc. or according to clients application

5, Glowing color: Yellow-green, Blue-green, sky-blue.

6, High concentration, Excellent dispersingWon't cause any bad effect to material propertyExcellent performance decrease your cost and increase your profitsSpecifications of glow in the dark masterbatch

| Appearance (Surface color) | White with light yellow |

| Additives | Dispersion agent, processing aid |

| Processing temperature |

|

| Heat resistance |

|

| Light fastness | 4-5 |

| Migration resistance | 5 |

| Carrier resin | Non or yes |

| Pellet Size | 4x4 (±0.5) mm, 3x3(±0.5)mm |

| Packing | 25kgs per bag |

| Storage | Keep at dry condition |

Luminescent plastics master batchLuminescent plastics master batch is a kind of plastics pellet that has the characteristics of self-glowing. By injection, extrusion and blowing molding, you can use photoluminescent plastic pellets directly to make luminous plastic products.Our photoluminescent plastic pellets are particularly for certain resins such as PP, PE , ABS, PC,PVC etc. Our standard percentage of the photoluminescent pigment in the photoluminescent plastic pellets is from 20% to 50%. The brightness and afterglow time of your finished products could be adjusted by yourself by adding more resins into the compounds.

1. Strong spontaneous illuminating capabilities: absorb light in bright places and emit light in dark places.

2. Heat to melt and cool to solidify. No chemical reactions in heating.

3. The same heating temperature with that for plastic resin.

4. Strong abilities in reducing dust pollution, enhancing products functionality.Why do you choose this products:Many customers like to use photoluminescent pigment directly Some of them found that there is blacken phenomenon. If you have fewer knowledge of photoluminescent pigment, this blacken phenomenon is hard to solve. And finally, the appearance of the finished plastic products looks not very good. The photoluminescent plastic pellets and master batch could help you overcome this difficulty.The photoluminescent pigment is in powder form. If you use photoluminescent pigment directly, the dust of the powder will do harm the environment and the heath of your staffs. The photoluminescent plastic pellets and master batch are in granule form, no one can be hurt now!